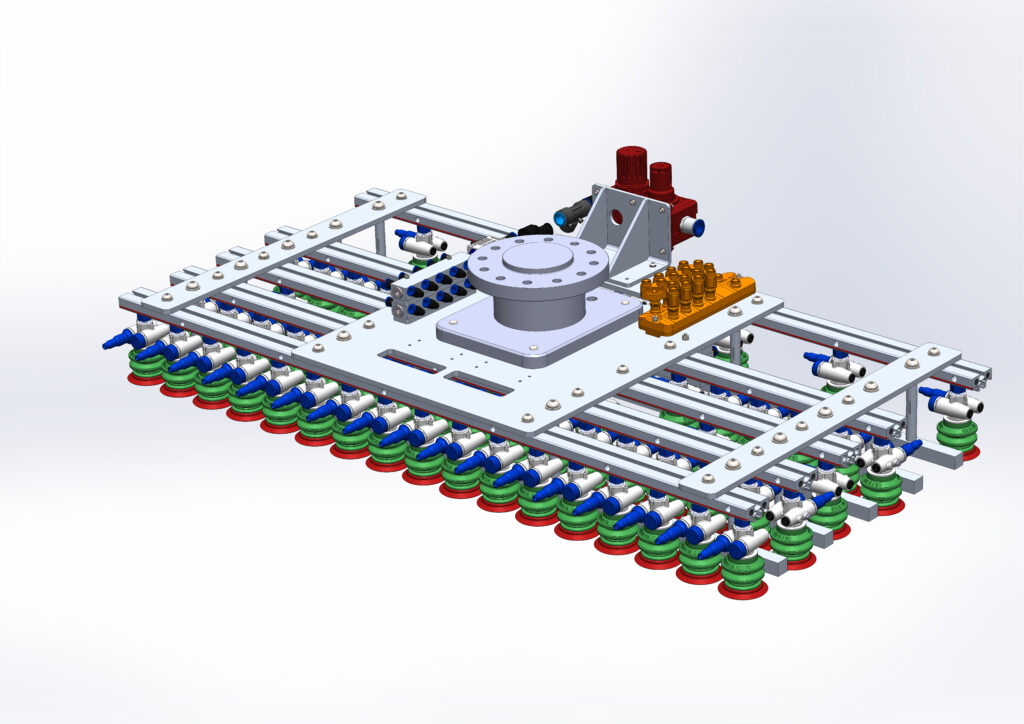

Here at Simmatic Automation we invite companies to challenge us with their difficult to handle products. We were tasked to design and manufacture four vacuum grippers to fit directly onto four ABB IRB660 palletising robots and capable of handling a range of box sizes, with varying weights, for an end of line palletising cell. Our design, created by Thomas Greenow-Langford, includes a range of products from VMECA‘s catalogue integrated to create this end of arm tool for the robots. The pick and place boxes range in size from 210mm x 210mm up to 800mm x 600mm and weighing up to 25kg.

Palletising Robots

This specific gripper utilises the independent vacuum generated by each magic gripper, to give the strongest hold on every box. There are four working zones to cope with the variety of boxes alongside a blowback feature on each Magic Gripper to help clear both the internal filters of the vacuum generators, and also, to clear the surface of the pick face from any dust prior to picking.

As part of the assembly at Simmatic we were able to integrate multiple vacuum switches, sensors and valves into one complete solution, where all leads were terminated back to an IFM IO-Link block. This allows the end user to control all the functions of this gripper with a single ethernet connection.

Here’s Ben Priest, our Sales Support Engineer, on site offering on hand support with small modifications to improve performance…

VMECA’s robot palletising applications using Magic Grippers offer several benefits to various industries. Here’s some of the advantages:

1. Increased Efficiency: The Magic Gripper allows for faster palletising, reducing the cycle time required to stack products onto the pallet. This results in increased productivity and cost savings for the company.

2. Versatility: The Magic Gripper can handle various product shapes and sizes, making it ideal for palletising applications that involve different types of products.

3. Reduced Risk of Product Damage: The Magic Gripper is designed to be gentle on the products, reducing the risk of damage during the palletising process. This is especially important for fragile items such as glass bottles or delicate food products.

4. Improved Safety: With the use of a robot and Magic Gripper, the palletising process can be fully automated, reducing the risk of injury to workers.

Challenge us with your difficult to handle products. Contact the team here at Simmatic with details of your vacuum application. We can show you how to solve all your industrial vacuum handling applications.