3D printed end of arm tooling is strong but light, highly conformal and can be rapidly iterated for a fraction of the cost of traditional tooling. Simmatic can 3D print bespoke End of Arm Tools (EOAT).

– Our Ultimaker S5 3D printer is equipped with a large build volume: 330 x 240 x 300 mm (13 x 9.4 x 11.8 inches)

– Compatible with a wide range of materials such as, PLA, ABS, Nylon 6, high-strength glass, carbon fibre filaments and many more

– Ability to print down to 20-micron (0.02mm) layer resolution and maintain a positional accuracy of 6.9 microns (X axis) 6.9 microns (Y Axis) 2.5 microns (Z Axis)

Take a look at our printer in action…

Bespoke 3D Printing

This purpose-built support vacuum end effector was 3D printed in food safe nylon/FDA approved. Then fitted to a TP80 high speed SCARA Robot to pick and place sausage rolls every 0.6 seconds. Simmatic’s 3D printed vacuum support was integrated with a VMECA lightweight green vacuum pump and a soft FDA silicon oval food grade vacuum cup. In speed trials it achieved 100 pick and place per minute.

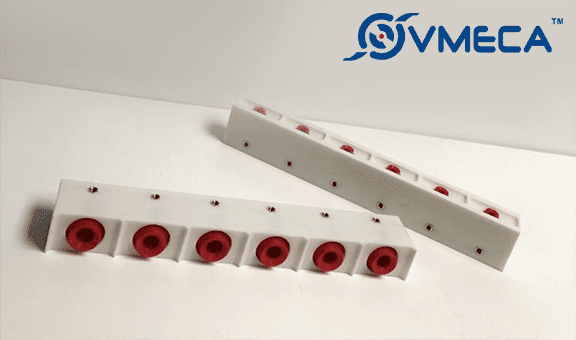

Here’s a 3D printed vacuum gripper with integrated VMECA VB20 & VB12 silicone vacuum cups…

The 3D printed support acts as a dimensional reference for the parts picked, giving solid, repeatable accuracy. Watch our video…

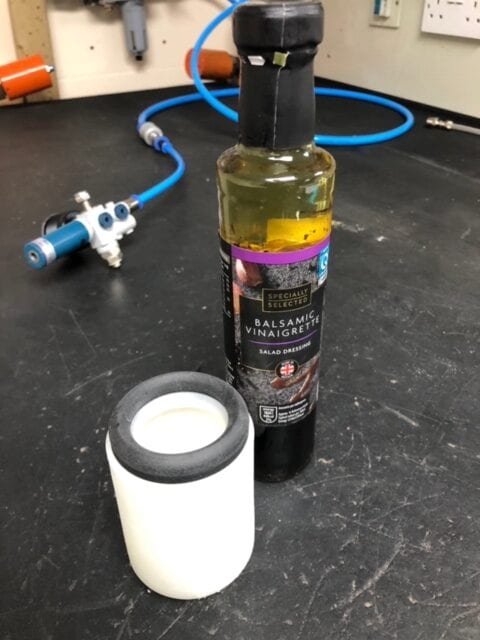

A bespoke 3D print vacuum end of arm tool fitted to a VMECA speeder module for picking and placing vinaigrette bottles.