The latest range of Turtle pumps from vacuum expert Simmatic feature a unique all-in-one design that enables big savings to be made in the cost and complexity of vacuum systems for applications as diverse as carton erecting, package handling and labelling.

In addition, because of their small size and robust construction, the pumps can, in most applications, be installed close to the point where the vacuum is needed. This ensures fast response to control signals – typically three times faster than conventional arrangements – and puts an end to the risk of leakage that is inevitably associated with long runs of pipework.

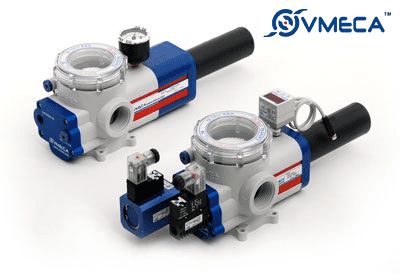

At the heart of every Turtle pump is an efficient multistage vacuum cartridge that operates from a compressed air supply and produces an almost constant level of vacuum over a wide range of air supply pressures. Each pump also incorporates an air control valve, a vacuum filter, a release control valve, a silencer and a vacuum gauge or switch. This fully integrated design means that few, if any external components are needed, which saves money, reduces installation time and simplifies pipework.

Uniquely, Turtle pumps feature self-cleaning vacuum filters. At each vacuum on-off cycle, dust is automatically cleared from the filter. This means that the pumps can operate for long periods without needing attention, that their performance does not degrade over time as the filter progressively clogs, and that the plant downtime associated with the regular cleaning of conventional filters is eliminated.

Turtle pumps from Simmatic are designed to work with compressed air supplies from 4.5 to 6 bar and, depending on the application, they can produce a vacuum of up to 95 -kPa. They are quiet in operation, generating noise levels of less than 60 dBA, and have an exceptionally wide operating temperature range of -20 to +80 ºC.